Power Products

in 3 Images or Less

ISSUE: September 2009

|

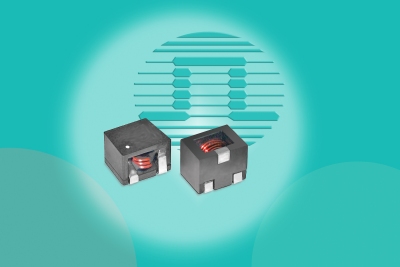

Round-Wire Inductors Outperform Flat-Coil Inductors From Pulse, a Technitrol Company, the PG0871NL and PG0702NL series of round-wire coil surface-mount power inductors use ferrite cores that reduce core loss by 90% and increase max operating temperature by 30% versus iron powder cores used in flat-coil inductors (Figs 1 and 2). Because ferrite material is immune to thermal aging, these inductors are more reliable and better performing at higher temperatures and frequencies than non-ferrite core inductors. The company also notes that the DCR of these round-wire inductors is less than that of flat-coil inductors. Additionally, the new inductors cost 25% less than flat-coil inductors. Inductance values range from 0.30 µH to 10.5 µH (Table). Target applications for these inductors include energy storage devices and filters in point-of-load (POL) dc-dc converters for telecom, datacom, server, and industrial applications. They are a lower-cost alternative to flat coil inductors for applications where very low profile is not a requirement. Another consideration when choosing between the round-wire and flat-coil inductors is their different pad locations. With the iron-powder core flat-coil inductors, the I/O pads are located at opposite ends of the core, while the ferrite-core round-wire inductors have pads on the same side of the core. This is mainly an issue when considering replacement of a flat-coil inductor in an existing design with one of the new round-wire inductors. In such a situation, a redesign of the pc board is required. Pricing is $0.35 each for the PG0871NL and $0.42 each for the PG0702NL in quantities of 50,000 pieces.

Fig 1. Pulse’sPG0871NL and PG0702NL series of round-wire coil surface-mount power inductors exhibit lower core loss and allow higher operating temperatures than flat-coil inductors with iron powder cores. Fig 2. A dc-dc converter design example illustrates the reduced core and winding losses offered by the ferrite-core round-wire inductors. In this example, losses were calculated for two comparable 3.3-µH inductors—a PG0871.332NL ferrite-core round-wire inductor and a PG0083.332NL iron powder-core flat-coil inductor. Higher DCR in the windings and higher core losses account for the higher overall losses of the PG0083.332NL. In this example the dc-dc converter is configured for VIN = 12 V, VOUT = 5 V, and switching frequency = 400 kHz. Table. Inductor Specifications

|