Power Products in 3 Images or Less

ISSUE: October 2009

|

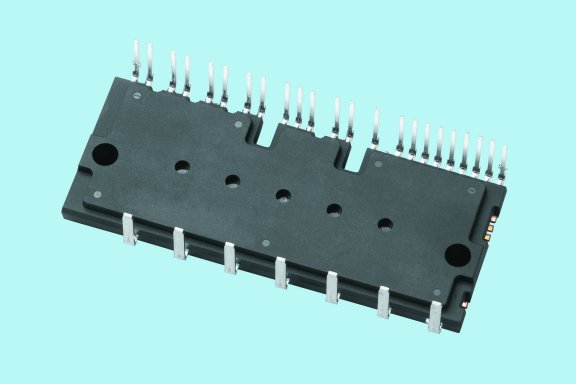

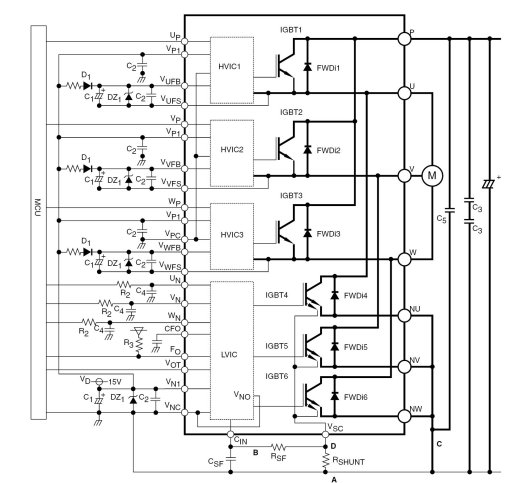

Intelligent Power Module Sets New Mark for Power Delivery Powerex’s new family of intelligent power modules (DIP-IPMs) sets a new benchmark for power delivery in a 79-mm x 31-mm dual inline package, delivering up to 75 A at 600 V in the PS21A7A (Fig 1). That represents a 50% increase in current-output capability compared to Powerex’s existing 600-V DIP-IPMs. The improved performance is attributed to the use of new packaging and semiconductor technology. On the packaging side, a proprietary resin reduces the thermal impedance of the package by 30% compared to the conventional resin used in previous DIP-IPMs (Fig 2). And at the die level, the efficiency of the IGBTs used in the modules is improved by their use of the latest Carrier Stored Trench Gate Bipolar Transistor (CSTBT) IGBT technology, which reduces power losses by 10% versus previous CSTBT technology. DIP-IPMs are intelligent power modules that integrate power devices, drivers, and protection circuitry. The use of these modules reduces design time for system designers because the modules provide the functionality of application-specific high voltage ICs (HVICs) together with features such as linear temperature feedback. (Fig. 3) This new family of DIP-IPMs provides the power stage needed in three-phase inverter applications for motors up to 20 HP and for both 230-Vac to 480-Vac lines. Typical applications include variable speed pumps, variable speed compressors and small motor control. The ability to cover both line voltages with a single package is due to the availability of these modules in 600-V and 1200-V ratings. In addition, to the PS21A7A, the family includes a 50 A, 600-V DIP-IPM (PS21A79), and a series of 1200-V modules with current ratings ranging from 5 A to 35 A (PS22A72 - PS22A78-E). In addition to increasing output power, the new DIP-IPM family features two other notable enhancements. The IGBTs integrate current mirrors for overcurrent protection. “This allows the use of small low power shunt resistors, says Eric Motto, Principal Engineer, Applications and New Product Development at Powerex. “Without this the 75-A part would have needed shunt resistors with a rating of 10 W or more.” The modules also include an integrated temperature sensor (in the LVIC) that generates a voltage feedback signal proportional to temperature. Other features include 2500 Vrms of isolation, operation from a single 15-VDC supply, an N-side open emitter, and RoHS compliance. Sample pricing ranging from $39 to $87 each, depending upon the rating selected.

Fig 1. Powerex’s new DIP-IPM family includes a model that delivers 75 A at 600 V. According to the vendor, this represents “the highest output power of any transfer mold Intelligent Power Module.”

Fig 2. Instead of relying on the molding resin of the package to provide electrical isolation from die to case (as in Gen 3), the new Gen 4 package employs a thin, electrically insulating resin sheet between the die and the heat spreader. This resin sheet has lower thermal resistance than the molding resin used in the rest of the package, so the thermal resistance from die to case is improved (Rth(j-c)) = 0.75 °C/W. Meanwhile, the undercut backside provides the spacing and clearance needed to achieve a 1200-V rating on devices rated up to 35 A.

Fig 3. As this application circuit for the PS21A79 illustrates, DIPIPMs co-package gate drivers with IGBTs to form highly integrated power stages for use in three-phase inverter applications. The gate drivers (labeled as LVIC and HVIC) also provide power supply under-voltage lockout, and short circuit protection. The drivers are optimized for the IGBTs to ensure short-circuit withstand capability. |