|

|

IN THIS ISSUE:

» Surprisingly Simple Control Method Slashes Vampire Power

» Verifying Safe Levels Of Hydrogen Diffusion In Wet Aluminum Electrolytic Capacitors

» Sense Current Over A Wider Range For Better Battery Management

» The Op Amp-Based Differential Amplifier: Not As Easy As It Looks

» Focus On Magnetics:

Designing Low-Power Flyback Inductors Using Tiny Toroids (Part 2): Calculating Losses

» Spotlight On Safety & Compliance:

Forms Vs. Function: Battling The Paperwork Deluge On Restricted Substances

» New Power Products

» Industry Events:

- ECCE 2019 Plenary Explores Power Electronics On The Grid, 99% Power Efficiency And More

- EOS/ESD Symposium Presents Best Practices, Emerging Technology And Hands-On Experiences

» Kudos2…

» Other Top Power News

From the Editor's Desk David G. Morrison

Editor, HOW2POWER TODAY

This July marks the tenth anniversary of How2Power.com. If you’ve been following this newsletter and visiting the website over the years, you’ve seen new features and sections added to provide more information on subjects such as magnetics design, safety and compliance, SiC and GaN devices, motor drives, test and measurement, EMI and power supplies for space and military applications. Among our most recent additions are the home page columns “FAE Confidential,” which discusses technical and business issues confronting power semiconductor FAEs, and “Power integrity Insights,” which seeks to enlighten power supply designers on the relevance of power integrity issues. The site has also grown by expanding existing sections such as our article search tool, the How2Power Design Guide, the Consultants Corner directory, and the extensive Industry Events section. The site and the newsletter offer technical information to engineers looking to design power converters or to use them in specific applications. Explore the site to find information that may help you solve your power design challenges. But also take advantage of the articles and resources that give insights into tech and industry trends. For example, browsing our design article and product news archives on the newsletters page is one way to observe trends in design techniques and component development that have emerged over the past 10 years. Yes, certain general trends in power supply development are eternal (higher efficiency, higher power density, more features), but then these often lead to refinements such as the push for lower standby power, which is discussed here in Tom Lawson’s article on Demand Pulse Regulation. As you read through the articles in this and future newsletter issues, it’s my hope you’ll find practical insights into industry trends that you can apply in your work along with the more concrete lessons about design techniques and new components.

|

|

|

|

|

HOW2POWER EXCLUSIVE DESIGN ARTICLES

|

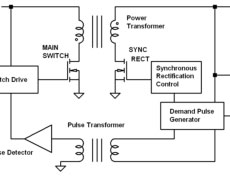

Surprisingly Simple Control Method Slashes Vampire Power

by Tom Lawson, CogniPower, Malvern, Pa.

There are billions of wall-mounted ac-dc converters in daily use, which collectively consume many gigawatts of power annually. Most of these chargers are doing nothing useful most of the time. They stay plugged in because it is hard to reach them where they tend to be found, down along the baseboard. Further, if they are left plugged in to the device they charge, the chargers are running at a very low percentage of their rated output just to keep the batteries topped up. So they run most of the time at very low efficiency. What is the best way to solve this problem of wasted energy, also known as vampire power? CogniPower's answer is make a more efficient charger with much lower standby power that is smaller and cheaper than the best of the current crop. A new control method known as Demand Pulse Regulation (DPR) makes these objectives possible.

Read the article…

|

By changing the feedback mechanism

and control circuitry, DPR lowers the

flyback converter’s power consumption in

standby while also reducing the

converter’s size and cost. |

|

As a safety concern, hydrogen

diffusion in wet aluminum electrolytic

capacitors is mainly relevant for

applications in which the capacitor is

housed in a sealed enclosure and

subject to a possible source of

ignition. |

Verifying Safe Levels Of Hydrogen Diffusion In Wet Aluminum Electrolytic Capacitors

by Wilmer Companioni, KEMET, Fort Lauderdale, Fla.

Aluminum electrolytic capacitors are widely used in the industry due to their relative high ratio of energy density to cost. In fact, they are used in such a wide variety of applications that many design engineers might overlook some aspects of the capacitor’s behavior based on its underlying technology. For example, it is important for design engineers planning to use wet aluminum electrolytic capacitors to consider and mitigate the diffusion of hydrogen. This article looks at hydrogen diffusion, how to determine the resulting levels of hydrogen that a wet electrolytic capacitor will produce in an application and whether these levels are safe. Safety in this case, means below the thresholds that would lead to ignition or even detonation of the hydrogen. This discussion is mainly relevant to applications in which the capacitor is housed in a sealed enclosure and subject to a possible source of ignition.

Read the article…

|

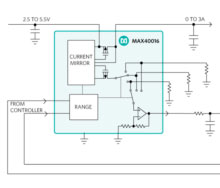

Sense Current Over A Wider Range For Better Battery Management

by Bonnie Baker, Maxim Integrated, San Jose, Calif.

In battery-powered portable and mobile devices, the proper way to determine the battery’s discharge status is to track the current outflow to the device over time. Some say that the appropriate solution to this current-sensing challenge is to use an ultra-small resistor value in the power-supply path followed by a difference amplifier. This appears to be an effective and appropriate solution. However, the hidden sensing resistor and following amplifier provide a somewhat restricted measurement range and require a relatively large PCB footprint. This article examines ways to overcome this challenge with an innovative solution to the current-sensing issues—one that uses an active sensing transistor alternative in the power supply's current path.

Read the article…

|

The MAX40016 current-sense amplifier

places an active sensing transistor in

the power supply's current path, providing

a 4X increase in dynamic range and 20x

PCB real estate savings versus a sense

resistor-based solution. |

|

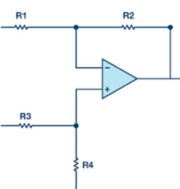

Given a value of R1 and a required gain,

we can select the values of the remaining

resistors, R2-R4, with the goal of setting

the input impedances equal. |

The Op Amp-Based Differential Amplifier: Not As Easy As It Looks

by Gregory Mirsky, Continental Automotive Systems, Deer Park, Ill.

When an inexpensive differential amplifier is needed, designers often use the familiar circuit and just choose resistor values to achieve equality of gains in both inverting and non-inverting branches, forgetting that the sources of the signals may have different output impedances. This impedance difference may completely destroy the differential amplifier operation, causing an output offset and compromising the common-mode rejection ratio (CMRR). Given a value of R1 and a required gain, we can select the values of the remaining resistors, R2-R4, with the goal of setting the input impedances equal. This article explains how to calculate those required resistor values, while also accounting for the variability of these values to initial tolerance, thermal coefficient of resistance, and aging.

Read the article…

|

|  |

FOCUS ON MAGNETICS

Sponsored by Payton Planar Magnetics

A monthly column presenting information on power magnetics design, products, or related technology |

Designing Low-Power Flyback Inductors Using Tiny Toroids (Part 2): Calculating Losses

by Dennis Feucht, Innovatia Laboratories, Cayo, Belize

Part 1 of this article described the design of a low-power flyback converter inductor using three stacked T20-26 cores — the smallest core in the Micrometals catalog. Here in part 2 we present further details of the inductor design, specifically the additional design formula required for determining the winding turn length of the unibundle-constructed 6-strand winding previously specified. This part also explains how to determine winding resistance and both core and winding power loss. Using this loss information, the effect of the inductor on converter efficiency, based on ideal output power, can be found. Does this design approximately balance core and winding losses to achieve optimum efficiency? If not, which loss dominates and why? The factors at play are explained and some conclusions are drawn about the usefulness of small cores in low-power converter designs. Read the full story…

|

|

|

SPOTLIGHT ON SAFETY & COMPLIANCE

Sponsored by Power Integrations

A monthly column discussing standards and regulatory requirements affecting power electronics |

Forms Vs. Function: Battling The Paperwork Deluge On Restricted Substances

by Kevin Parmenter, Chair, and James Spangler, Co-chair, PSMA Safety and Compliance Committee

Almost once a week or more the phone rings or an email arrives, usually from a top name brand company or on behalf of one, asking about our product’s compliance with environmental and hazardous materials regulations. I [Kevin] work for a semiconductor manufacturer, so the requests concern components we’re supplying to a customer. But anyone supplying any components, subassemblies or finished electronic instruments or equipment could be subject to such inquiries. The request comes from a far off land because it’s been outsourced to someone to get a form filled out. The good news is that people are paying attention to restricted materials regulations. However the bad news is that many customers are inflexible in the way they work with their suppliers to gather the needed information. In this article, the authors describe the problem, suggest some possible solutions, and point to some helpful resources. Read the full article…

|

|

|

— POWER PRODUCTS IN 3 IMAGES OR LESS — POWER PRODUCTS IN 3 IMAGES OR LESS

|

INDUSTRY EVENTS  |

|

ECCE 2019 Plenary Explores Power Electronics On The Grid, 99% Power Efficiency And More

by David G. Morrison, Editor, How2Power.com

With the IEEE Energy Conversion Congress & Expo (ECCE 2019) just a little more than two months away, details of the extensive technical program are coming to light, starting with the plenary session. The plenary at this year’s ECCE, which will be held Sept 29-October 3 at the Baltimore Convention Center in Baltimore, Maryland, will shine a light on developments in power electronics applications on the grid, in motor drives and in military systems. It will also present innovative ideas on more fundamental topics in power electronics such as co-design of power circuits and thermal management and the pursuit of ultra-high efficiency and power density. This article offers a preview of four of the talks. Read the full story…

|

The upcoming IEEE Energy Conversion

Congress & Expo (ECCE 2019) will be held

September 29-October 3 at the Baltimore

Convention Center—just a short walk from

Baltimore’s famous Inner Harbor.

|

|

EOS/ESD Symposium Presents Best Practices, Emerging Technology And Hands-On Experiences

by Brennan Pimpinella EOS/ESD Marketing Administrator

The EOS/ESD Symposium is the premier international event for professionals in industry and academia to network while immersed in the latest technical findings and innovative designs. The organizers of the first symposium, way back in 1979, would be shocked (no pun intended) at the enduring success and relevance of this event. Today, the EOS/ESD Symposium is well known as the premiere international gathering of ESD professionals. This status is a result of four key factors: 1) outstanding technical papers from both industry and academia, 2) close interaction and enduring support from industry exhibitors, 3) an amazing group of volunteers and 4) the wonderful staff at ESDA headquarters. Here is a short summary of what to expect at our event, which will take place September 15-20 in Riverside, Calif. Read the full story…

|

|

KUDOS2…  |

|

Victor Veliadis, who was recently named executive director of PowerAmerica. Under Veliadis’ tenure as deputy director and CTO, PowerAmerica has grown into a world-class Manufacturing USA institute accelerating wide-bandgap power electronics commercialization and creating jobs in advanced technology. Victor Veliadis, who was recently named executive director of PowerAmerica. Under Veliadis’ tenure as deputy director and CTO, PowerAmerica has grown into a world-class Manufacturing USA institute accelerating wide-bandgap power electronics commercialization and creating jobs in advanced technology.

Apex Microtechnology, which has been awarded a 5-Star Supplier Excellence Award by Raytheon’s Integrated Defense Systems business. Apex Microtechnology, which has been awarded a 5-Star Supplier Excellence Award by Raytheon’s Integrated Defense Systems business.

|

OTHER TOP POWER NEWS

|

|

A call for papers has been issued for the annual IEEE Long Island Section Power Electronics Symposium, which will be held November 7, 2019 in Hauppauge, NY. Now in its third year, last’s year’s symposium drew over 400 attendees—primarily engineers from local industry. The event also featured an expo with over 40 companies showing their products and services. A call for papers has been issued for the annual IEEE Long Island Section Power Electronics Symposium, which will be held November 7, 2019 in Hauppauge, NY. Now in its third year, last’s year’s symposium drew over 400 attendees—primarily engineers from local industry. The event also featured an expo with over 40 companies showing their products and services.

PCIM Asia, a unique platform for power electronics in Asia, closed its doors after a successful three days from June 26 to 28, 2019. A total of 81 exhibitors presented the latest trends, developments and product innovations for all application areas of power electronics. The conference also achieved a good result with 407 participants. PCIM Asia, a unique platform for power electronics in Asia, closed its doors after a successful three days from June 26 to 28, 2019. A total of 81 exhibitors presented the latest trends, developments and product innovations for all application areas of power electronics. The conference also achieved a good result with 407 participants.

A tutorial on “Energy Harvesting (EH) for the Industrial IoT” will be presented by Brian Zahnstecher at the upcoming ECCE 2019 conference. A tutorial on “Energy Harvesting (EH) for the Industrial IoT” will be presented by Brian Zahnstecher at the upcoming ECCE 2019 conference.

PEMD 2020, the International Conference on Power Electronics, Machines and Drives, has issued its call for papers. The conference will be held April 21–23, 2020 in Nottingham, UK. PEMD 2020, the International Conference on Power Electronics, Machines and Drives, has issued its call for papers. The conference will be held April 21–23, 2020 in Nottingham, UK.

The PCIC, a premier conference for practicing electrical engineers and other professionals that deal with electrical installations in the oil and gas industry, has issued a call for papers for next year’s conference, which is to be held September 14-17, 2020 in Atlanta, GA. The PCIC, a premier conference for practicing electrical engineers and other professionals that deal with electrical installations in the oil and gas industry, has issued a call for papers for next year’s conference, which is to be held September 14-17, 2020 in Atlanta, GA.

|

|

|  |

ABOUT THIS NEWSLETTER: Thank you for reading HOW2POWER TODAY.

How2Power sends no more than one e-mail per month to registered users. Continuing your subscription ensures you'll receive future newsletters. Manage Your Subscription

©2019 All rights reserved. www.how2power.com

|

|