|

|

IN THIS ISSUE:

» Current-Mode Controlled DC-DC Regulators (Part 4): Small-Signal Behavior Of The CC Loop

» Controlling Rogowski Sensor Frequency Response Through Integrator Design

» Motor Control For Designers (Part 3): Torque-Current Relationship

» Focus On Magnetics:

The Ćuk Integrated Magnetics Converter With Current Ripple Cancellation: The Optimal Power Conversion Topology?*

» Special Guest Commentary: Optimizing Power Density In Power Converters: The Role Of Top-Side-Cooled Packages

» Power Products

» Special Guest Commentary: Meeting Medical System Needs With Configurable Digital Power

» Industry Event: 3D-PEIM

» Other Top Power News

From the Editor's Desk David G. Morrison

Editor, HOW2POWER TODAY

The advertisement for a vendor seminar* on liquid cooling solutions proclaims, “AI is evolving data centers faster than ever before, and traditional cooling methods won’t keep up. The industry needs to change. Liquid cooling is no longer optional…” This assertion would seem to be supported by the long list of presentations on liquid cooling at the OCP Global Summit, which is being held this week in San Jose. Cooling talks seem to be even more prominent than power topics at this event hosted by the Open Compute Project. While power-hungry processors are no doubt driving the requirements for liquid cooling in data centers, power supplies stand to benefit as well from the development and proliferation of liquid cooling solutions—both in data centers and beyond. As power electronics continues its eternal pursuit of higher power density in a range of applications, liquid cooling becomes inevitable in more of them. I suspect that liquid cooling technologies and the practical details of applying them will become more frequent subjects of papers and presentations in many power electronics forums just as packaging topics, in general, have garnered greater attention over time. This issue of How2Power Today touches on both cooling and packaging at the device level, first in an article discussing top-side cooling of MOSFETs and then in a report on the recent 3D-PEIM Symposium. This newsletter also presents an eclectic mix of features on other matters. For example, we have an analysis of the Ćuk topology with integrated magnetics, which assesses how well the Ćuk converter delivers on its promises of greater performance. Additional articles discuss design for frequency bandwidth in Rogowski sensors, analysis of the CC loop in a CC-CV regulator with dual-loop architecture, an explanation of the torque-current relationship in motors, the benefits of configurable digital power supplies for medical systems, and more.

* by Schneider Electric

|

|

|

HOW2POWER EXCLUSIVE DESIGN ARTICLES

|

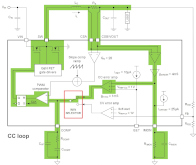

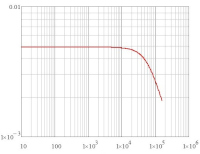

Current-Mode Controlled DC-DC Regulators (Part 4): Small-Signal Behavior Of The CC Loop

by Timothy Hegarty, Texas Instruments, Phoenix, Ariz.

In part 3 of this series, the author defined a CC-CV regulator with a novel dual-loop architecture activating either the CC or CV error amplifier at a given time, thus minimizing loop interactions and yielding a seamless handoff from CC to CV and vice versa. He then described a synchronous buck controller with this CC-CV implementation that offers accurate current-regulation performance, a low external component count and reduced cost. This fourth installment builds on part 3 by pursuing the relevant small-signal transfer functions for the CC loop. Designing the CC and CV loops with similar small-signal dynamics enables the use of a shared compensation component network. Bode plot simulations of the loop response in CC mode, based on a commercially available CC-CV GaN synchronous buck converter (the LMG708B0), illustrate the small-signal characteristics of the dual-loop architecture. Read the article…

|

This installment examines the small-signal

behavior and the compensation of the CC loop

of a CC-CV regulator with a novel dual-loop

architecture. |

|

By tweaking the value of the inverting

integrator’s feedback resistor one can

adjust the bandwidth of the Rogowski

sensor to better represent the measured

current waveform. |

Controlling Rogowski Sensor Frequency Response Through Integrator Design

by Gregory Mirsky, Design Engineer, Deer Park, Ill.

In a previous article series, the operation of the Rogowski coil was analyzed and equations were derived for designing both the coil and integrator to create a complete Rogowski sensor. The purpose in doing so was to allow designers to obtain some of the benefits of Rogowski sensors such as wide current range at a much lower cost than off-the-shelf instrument-grade Rogowski sensors, while only making small sacrifices in sensor accuracy. In this article, we carry the discussion design further by explaining how to tailor the frequency bandwidth of the Rogowski sensor to a particular application through adjustment of the integrator design. This part also draws on some of the analysis performed in the recent series on integrators. Read the article…

|

Motor Control For Designers (Part 3): Torque-Current Relationship

by Dennis Feucht, Innovatia Laboratories, Cayo, Belize

With the definition of terms and key relationships established in the first parts of this series, we can now proceed to develop a motor model in the next three parts. As an electromechanical device, it will have certain relationships between electrical and mechanical quantities. This part relates electrical and mechanical quantities in two simple equations for torque T and induced voltage vω. We begin by deriving these expressions, and then describe how motor geometry influences the induced-voltage waveform. This relationship is further illustrated by presenting the flux and induced-voltage waveforms for a simple PMS motor example. Read the article…

|

As a magnet edge sweeps across the

face of a winding, a rotor flux change

penetrates the winding loop area. The

magnet field Br induces voltage vω into

the winding in proportion to the rate

of flux change. |

FOCUS ON MAGNETICS

Sponsored by Payton Planar Magnetics

A monthly column presenting information on power magnetics design, products, or related technology |

The Ćuk Integrated Magnetics Converter With Current Ripple Cancellation: The Optimal Power Conversion Topology?*

by Isaac Cohen, Huntington Station, N.Y.

It’s claimed that the Ćuk converter is superior to other topologies (operating at the same frequency) because it offers zero (very low) current ripple at both input and output; inductive energy storage replaced by capacitive energy storage, leading to lower cost and smaller volume; dc current in the inductor, eliminating ac copper loss; and higher efficiency. However, to the best of the author’s knowledge, no rigorous quantitative comparison was ever done to validate the narrative and quantify the advantage in power density and efficiency. In this presentation, a simple model is developed for easy simulation of the Ćuk converter. The Ćuk converter with integrated magnetics is then analyzed and compared to an equivalent flyback converter operating at the same frequency. Some conclusions are drawn about the claimed benefits of the Ćuk converter.

Read the article…

*This presentation is meant to be viewed as a slide show. For best viewing, select “Fit to width,” the presentation mode or the equivalent in your browser.

|

|

|

|

|

SPECIAL GUEST COMMENTARY

|

|

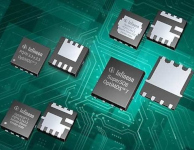

Optimizing Power Density In Power Converters: The Role Of Top-Side-Cooled Packages

by Josef Wildauer, Infineon Technologies, Villach, Austria

Power electronics are evolving rapidly, with new materials and packaging technologies driving efficiency gains and enabling higher power densities. A key enabler of this transformation is the integration of advanced packaging technologies like Infineon’s top-side-cooled (TSC) Q-DPAK packages. These packages, which separate the thermal and electrical paths, significantly enhance the performance of power converters. While silicon MOSFETs have traditionally dominated power conversion applications, the benefits of top-side cooling are now being realized across silicon and SiC-based devices, offering higher efficiency, faster switching speeds, and the ability to operate at elevated temperatures. This article explains the thermal and electrical advantages offered by MOSFET packages with top-side cooling and how to optimize the PCB layout and configuration of the switching cells. Techniques for optimizing board layout are validated by testing a full-bridge eval board with TSC SiC MOSFETs. Read the full story…

|

|

|

POWER PRODUCTS  |

Infineon Technologies’

OptiMOS 7 power MOSFETs. |

MOSFETs Are Optimized For Industrial And Consumer Applications

Photo: The 25-V MOSFETs are tailored to switching applications, including hard-switching-optimized devices featuring an excellent Miller ratio, FOMs, and RDS(ON), and soft-switching-optimized products delivering ultra-low RDS(ON) and FOMQg. The 40-V MOSFETs are designed for motor-drive applications, delivering lower RDS(ON), optimized gate characteristics, enhanced noise immunity, and a threefold-wider SOA compared to the previous generation. Photo: The 25-V MOSFETs are tailored to switching applications, including hard-switching-optimized devices featuring an excellent Miller ratio, FOMs, and RDS(ON), and soft-switching-optimized products delivering ultra-low RDS(ON) and FOMQg. The 40-V MOSFETs are designed for motor-drive applications, delivering lower RDS(ON), optimized gate characteristics, enhanced noise immunity, and a threefold-wider SOA compared to the previous generation.

See the full story…

|

Microchip Technology’s

DualPack 3 power modules. |

IGBT Modules Offer Higher Power Density And 1200-V To 1700-V Ratings

Photo: Targeting motor drive, data center and sustainability applications, the six IGBT power modules use the latest IGBT7 technology, engineered to reduce power losses by up to 15% to 20% compared to the company’s IGBT4 devices and operate reliably at higher temperatures up to 175°C during overload. The modules enhance protection and control during high-voltage switching. Photo: Targeting motor drive, data center and sustainability applications, the six IGBT power modules use the latest IGBT7 technology, engineered to reduce power losses by up to 15% to 20% compared to the company’s IGBT4 devices and operate reliably at higher temperatures up to 175°C during overload. The modules enhance protection and control during high-voltage switching.

See the full story…

|

Nexperia’s 100-V MOSFETs

in CCPAK1212 packaging. |

100-V Automotive-Qualified MOSFETs Deliver Low Conduction Losses

Photo: With their compact 12-mm x 12-mm footprints, these packages offer two cooling options: bottom-side cooled CCPAK1212 and inverted, top-side cooled CCPAK1212i. These packages deliver up to 1.5-kW power ratings, low electrical and thermal resistance, high current density, and best-in-class SOA performance, according to the vendor. Photo: With their compact 12-mm x 12-mm footprints, these packages offer two cooling options: bottom-side cooled CCPAK1212 and inverted, top-side cooled CCPAK1212i. These packages deliver up to 1.5-kW power ratings, low electrical and thermal resistance, high current density, and best-in-class SOA performance, according to the vendor.

See the full story…

|

Advanced Energy Industries’

Artesyn NDQ1300 and NDQ1600

bus converters. |

1300-W And 1600-W Quarter-Brick Bus Converters Are Highly Efficient

Photo: The quarter-brick modules convert 48 V to 12 V with peak efficiencies up to 98%, benefitting high-end ICT and industrial applications. Photo: The quarter-brick modules convert 48 V to 12 V with peak efficiencies up to 98%, benefitting high-end ICT and industrial applications.

See the full story…

|

|

|

SPECIAL GUEST COMMENTARY

|

|

Meeting Medical System Needs With Configurable Digital Power

by Nate Mandelko, Advanced Energy, Eden Prairie, Minn.

Large-scale, high-power medical devices—such as diagnostic imaging scanners and surgical or cosmetic laser systems—often present complex power design requirements. These challenges are driven by the need to support numerous digital and analog subsystems, as well as arrays of sensors and actuators operating at varying, often non-standard, voltages. Further complexities can emerge from elements like battery chargers and capacitor banks, which provide pulsed energy to lasers and frequently require stable constant-current supplies. Adding to these are strict safety and isolation requirements, especially limits on leakage current for medical equipment designers. Faced with such varied yet exacting requirements, finding an off-the-shelf, medical-approved multi-output ac-dc power supply tailored to the requirements of the application at hand is difficult. This article explains how configurable, digitally controlled power supplies can help. Read the full story…

|

INDUSTRY EVENT

|

|

3D-PEIM 2025 Focused On Higher Performance And Lower Costs In A Smaller Package

One hundred representatives from industry, academia, and research institutions gathered at the Fifth International 3D Power Electronics Integration and Manufacturing Symposium (3D-PEIM 2025), which was held July 8–10, 2025 and hosted by the National Renewable Energy Laboratory in Golden, Colorado. The symposium focused on power electronics packaging and technologies that achieve higher performance, better reliability, and lower cost in a smaller package through system integration. Read the full story…

|

OTHER TOP POWER NEWS

|

|

Empower Semiconductor has secured over $140M in Series D financing by investors including CapitalG, Alphabet's independent growth fund. Empower Semiconductor has secured over $140M in Series D financing by investors including CapitalG, Alphabet's independent growth fund.

onsemi has entered into an agreement with Aura Semiconductor to acquire rights to its Vcore power technologies. onsemi has entered into an agreement with Aura Semiconductor to acquire rights to its Vcore power technologies.

|

Infineon will supply Goldwind with its XHP 2 1700-V IGBT5 power modules with .XT technology that will enhance energy efficiency in Goldwind’s grid-forming wind turbines. Infineon will supply Goldwind with its XHP 2 1700-V IGBT5 power modules with .XT technology that will enhance energy efficiency in Goldwind’s grid-forming wind turbines.

Empower Semiconductor’s Crescendo chipset, an AI and HPC processor true vertical power delivery platform, is available now for final sampling, with mass production slated for late 2025. Empower Semiconductor’s Crescendo chipset, an AI and HPC processor true vertical power delivery platform, is available now for final sampling, with mass production slated for late 2025.

Electreon and ATLoS have partnered to integrate wireless charging into autonomous industrial vehicles. Electreon and ATLoS have partnered to integrate wireless charging into autonomous industrial vehicles.

iDEAL Semiconductor has announced Polar Semiconductor as a manufacturing partner for its SuperQ power devices. iDEAL Semiconductor has announced Polar Semiconductor as a manufacturing partner for its SuperQ power devices.

ABOUT THIS NEWSLETTER: Thank you for reading HOW2POWER TODAY.

How2Power sends no more than one e-mail per month to registered users. Continuing your subscription ensures you'll receive future newsletters. Manage Your Subscription

©2020 All rights reserved. www.how2power.com

|

|